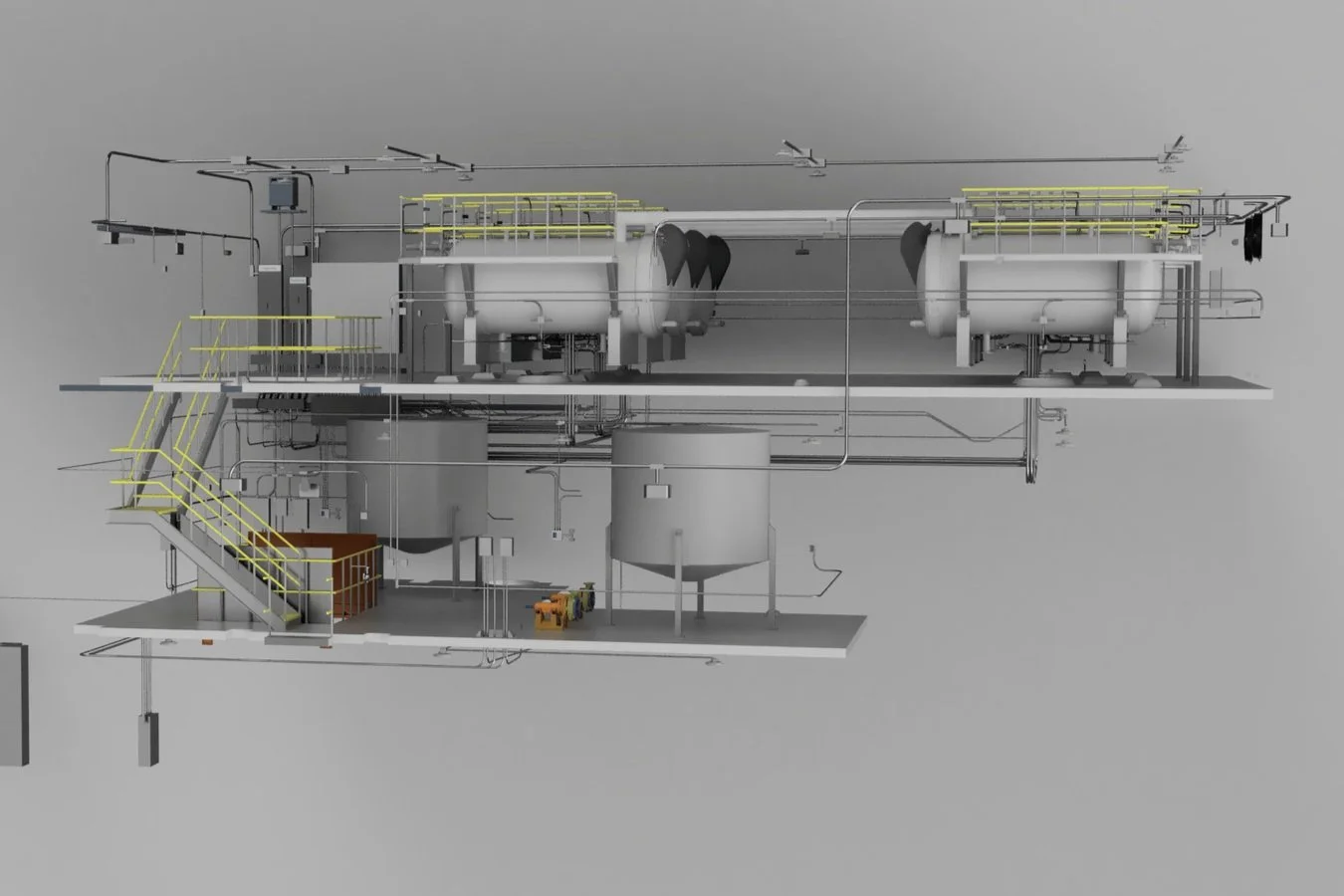

Total Process Engineering

Our team has extensive experience in designing and improving various processes, including hygienic design, across diverse industries and locations. We enhance existing systems by applying engineering principles and expertise in multiple process types. With our deep knowledge of design and plant operations, we tailor our process designs to meet the latest energy efficiency and industry standards while ensuring ease of operation and maintenance.

Service Benefits:

Maximize Efficiency:

Streamline operations to minimize waste and boost productivity.Reduce Operational Costs:

Implement cost-effective processes to optimize resource use.Enhance Product Quality:

Achieve consistent, high-quality outcomes with precision-engineered processes.Scalable Solutions:

Prepare for growth with flexible, adaptable process engineering services.

What You Can Expect

Our process begins with an initial design review to align with your expectations and project goals. We collaborate closely with both our internal team and the client to ensure compliance with local regulations and adherence to the project timeline. We then conduct a root cause analysis to identify underlying issues and develop practical solutions, which may include updating procedures or engineering new equipment.

Throughout the project, we hold regular design review sessions to verify accuracy and ensure your satisfaction. Upon completion, we provide detailed drawings and offer ongoing support as needed.

Frequently Asked Questions

-

Yes, we can document existing systems with our extensive process knowledge and troubleshoot various new processes to identify and resolve issues.

-

Process engineering involves designing, operating, and optimizing industrial processes, benefiting businesses by improving efficiency, reducing costs, ensuring regulatory compliance, and enhancing product quality.

-

We specialize in industries like manufacturing, pharmaceuticals, chemicals, food and beverage, energy, and municipal services. We handle both new process design and optimization of existing processes.

-

We stay current with industry regulations, conduct thorough audits, and use leading software like Aspen Plus, HYSYS, AutoCAD, and specialized tools to ensure all processes meet compliance requirements.

-

We design processes that minimize waste, reduce energy consumption, and incorporate renewable resources. We also ensure that our designs are scalable to accommodate your business growth.

-

Yes, we can share case studies of successful projects. We follow a structured project management approach with clear communication, defined milestones, and regular updates to ensure adherence to timelines.

-

Safety is a top priority; we conduct comprehensive risk assessments and implement safety protocols. We also have experience in digital transformation, including IoT integration and Industry 4.0 technologies.

-

Yes, we provide comprehensive training for your team. We also ensure seamless integration of new technologies into existing processes with minimal disruption.

-

Costs vary based on project scope, and we provide detailed estimates after an initial consultation. We offer ongoing support through project completion, including assistance with RFIs and project management.